PROJECTS

MAJOR COMPLETED PROJECTS

OUR CAPABILITIES AND CORE COMPETENCIES ARE OUTLINED IN THE CASE STUDIES BELOW.

CRA: Woodside Energy

Project: NY FPSO (Offshore)

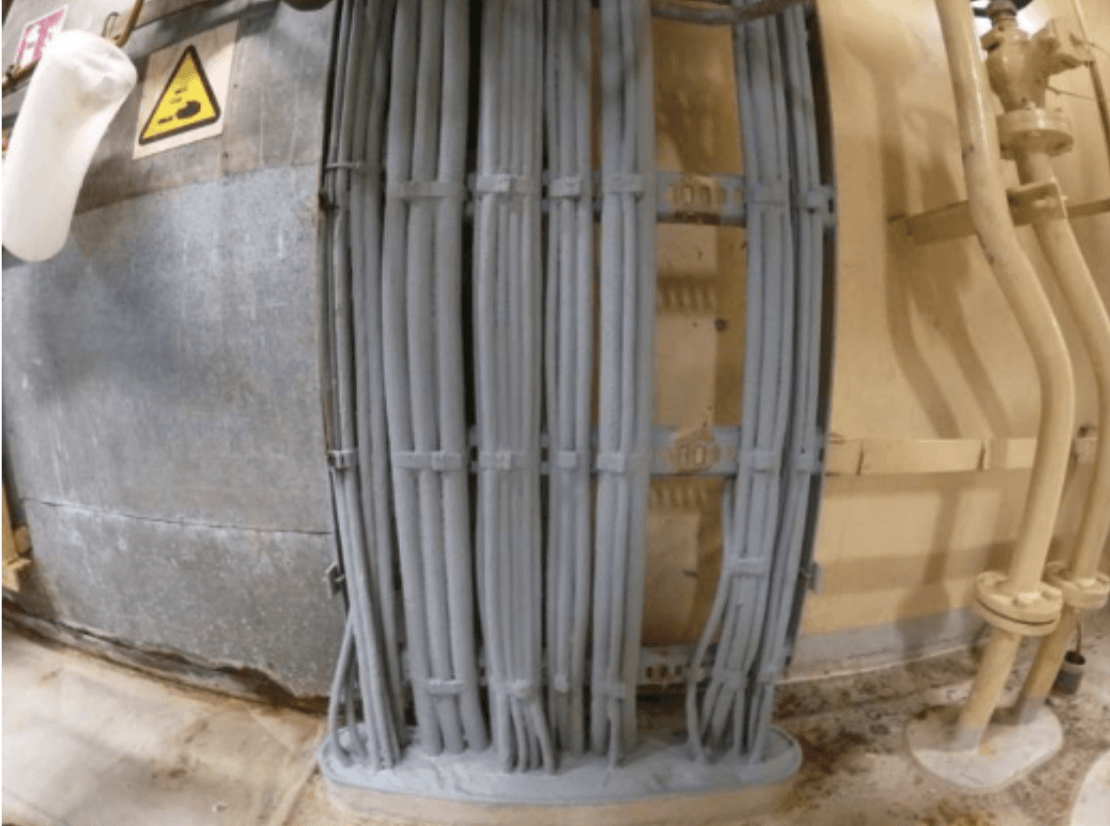

Brief: The purpose of this project was to repair corrosion damaged outer armored cables within the engine room of the vessel.

Details: Exposure to moisture has caused the corrosion, interrupting the connection to earth. Damage ranged from unaffected or lightly corroded all the way to rusted — which is expected in a vessel of this size. Cables with rusted armor were cut back until a reasonable condition was found. Then, they were covered with Fire Security’s FS18 Tinned copper shielding tape, and that tape was further secured using FS17 splice tape, creating a sealed layer. This repair area was then coated with a fire-proof cable coating (FS5), which was also applied to individual cables and bundles/trays of cables. Our repair method is tested and approved by DNV and ABS for use on offshore installations and ships.

Outcome: More than 40 individual cables were repaired and around 120 meters of armor rebuilt. Around 400 meters of cable bundles and trays were cleaned and coated with FS5. Aside from fire-proofing, the FS5 coating also upgraded the cables insulation value and increased the life expectancy of the cables outer sheath because it’s resistant to UV, Ozone, oil, mud, chemicals, and water/seawater.

CRA: Woodside Energy

Project: Karratha Gas Plant – Substations 1 & 2 (Onshore)

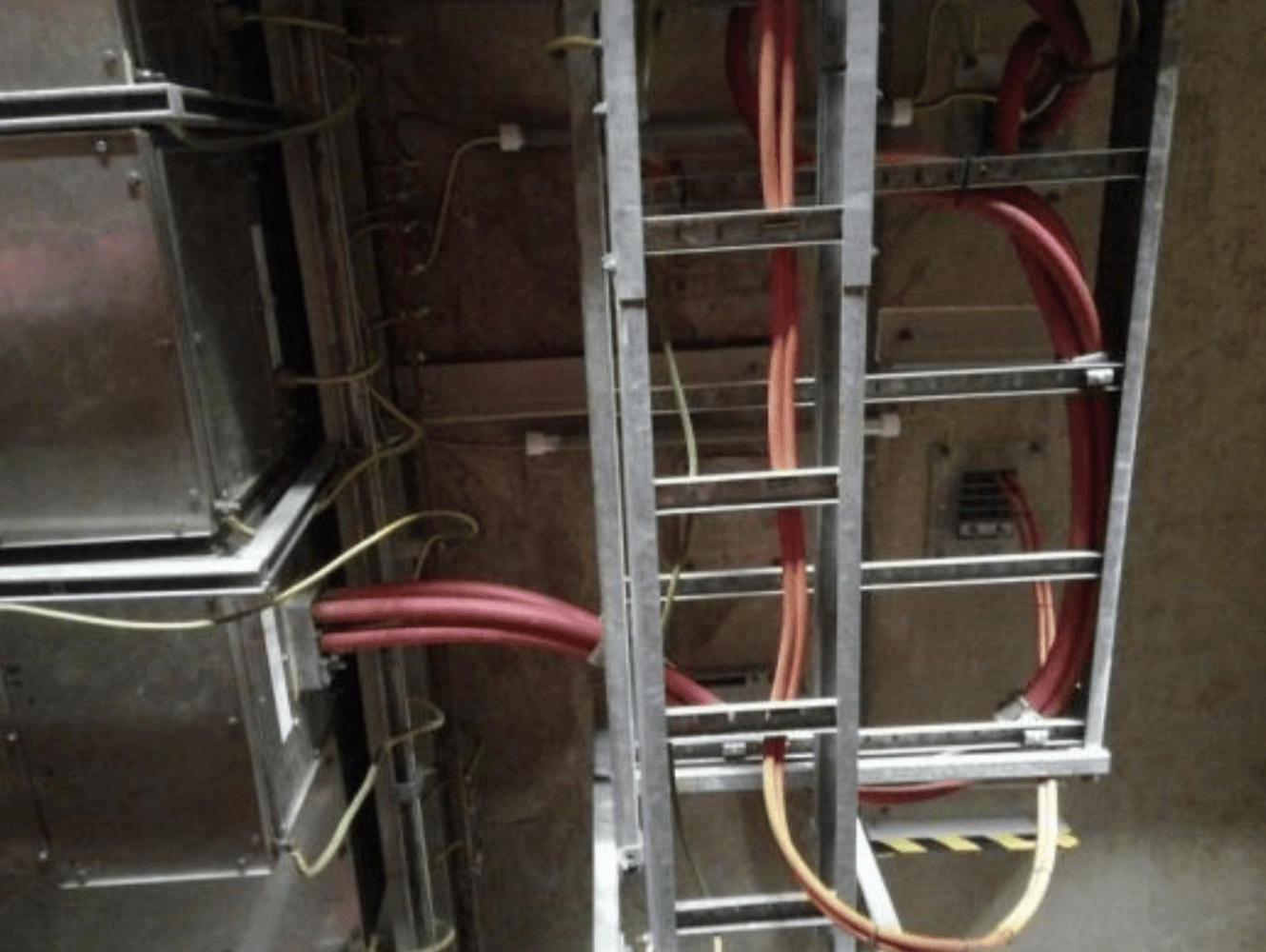

Brief: The purpose of this project was to fire protect vital cables located below substations 1 and 2.

Details: A selection of cables installed on the 33KV switchboard were measured to be high-risk and vital. As a result, we coated them with our FS5 Class approved fire-resistant coating to increase the fire rating of the cables. We also coated an area of the mortar used to seal cable transits in the substation floor, as this mortar has previously had bees boring through this material and entering the substation.

Outcome: The project was carried out during a shutdown/turnaround, but did not impede operations in any way. We’re pleased to say our team executed the scope of work in five days, including travel, safety induction, and pressure testing of all spray equipment. We also gave KPG recommendations on future preventive works that could be carried out to cost-effectively extend the life of their cables.

CRA: Vermilion Energy

Project: Wandoo B Platform

READ TESTIMONIALS

Brief: The scope of work was to restore and project all UV exposed cables platform wide and to remove cable tray covers, which were deemed a hazard during cyclone season.

Details: Our crew, along with a rope access team, prepared the platform and started applications and tray cover removal the following day. Two areas on the main deck were not able to have the tray covers removed and coating applied due to operational restrictions and safety concerns. To cater to this, alternative additional locations of semi-UV exposed cable runs were coated here instead. All other UV exposed areas were successfully coated with blue or red colour coding used, and cable ID tags left visible.

Outcome: Despite potentially hazardous high-speed winds, the project went very well, maintaining all safety standards and was completed within the scheduled time.

CRA: Woodside Energy

Project: Pluto LNG Plant

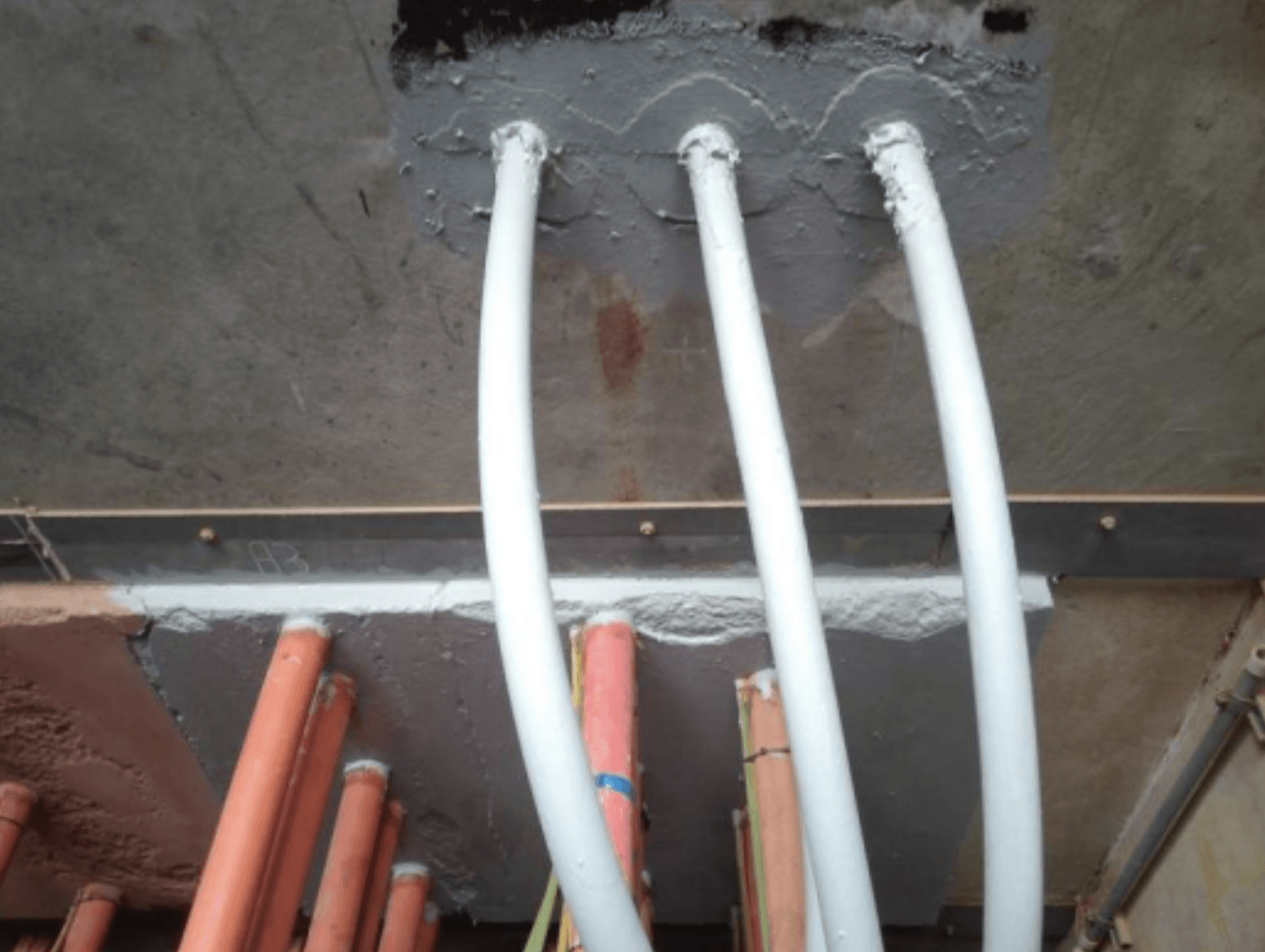

Brief: CRA was engaged prior to a major statutory shutdown by Woodside to repair damaged cables on all 24 PLUTO LNG cranes.

Details:

The work was a prerequisite prior to the shutdown or else they couldn’t be used. CRA has to deliver on time or else the shutdown would be delayed. The cables were both UV damaged and or sheared around entry boxes due to poor installation where the cables were bent under tension. CRA spent a month on site prior to the shutdown repairing the cables on all cranes. There was a combination of cable repair and coat utilising FS5.

The job was done while Pluto LNG was operational and was done on time and under budget.

Outcome: CRA was subsequently put on WOODSIDE’s approved vendor list and is currently assisting Woodside with scoping up work for KGP life extension programme and further work on Pluto LNG.

Fire Security: KS Java Star Repair of Fire Damaged High Voltage Cables

Project:

Cable Repair on Jack Up Rig KS Java Star

Brief:

To repair the fire-damaged HV cables and cable-jackets on the KS Drilling jack up rig in the North Java sea, with minimal disruptions to drilling operations.

Details:

- Removed the damaged outer sheath.

- Cleaned cables.

- Applied linerless rubber tape to all damaged cables.

- Applied a thick layer of coating, then a fibre mesh for additional mechanical strength.

- Let the coating dry and cure for 24 hours.

- Applied a second and third layers of coating.

- Cable repair finished.

Outcome:

- All cables were repaired while energized.

- No electricity shutdown was required during the work or as a result of the work.

- The lifetime of the cables has been greatly extended, and they are now functioning as they were before the incident.

CONTACT US FOR A QUOTE ON YOUR NEXT CABLE PROJECT

NAVIGATE

© Cable Restoration Australia Pty Ltd. Terms and Conditions Credit Application Form